The manufacturing process for DOM tubing begins with coils of steel, which are slit to the proper width for the desired tube size. The strip is cold formed and passed through an electric resistance welder which joins the edges together, under pressure, to complete the tubular shape. After testing the weld’s integrity, the tubing is cut to length for further processing.

The cold-drawing process creates a uniform, precision product with substantially improved tolerances, surface finish and tensile strength, increased hardness and good machinability. In this process, the tube is cleaned and annealed, and one end of each length is squeezed to a point so it can be gripped by the drawing mechanism. The tube is then drawn through one or more dies and over mandrels. This reduces the diameter of the tube and thins its walls to the required dimensions in a controlled fashion to provide the qualities desired in the finished product. Metallurgically, drawing improves the tube’s concentricity, tensile strength, hardness and machinability. Close dimensional accuracy is achieved through tight control of both outside and inside diameters.

Pennar Global is your go-to supplier for your DOM tubing needs. The partnerships that we have developed with raw material suppliers as well as our carefully selected mill sources creates unmatched quality that will exceed your expectations. Our products have been utilized in many applications in these various industries including automotive, ATV/off road, fitness, furniture, agriculture, and many more.

Features

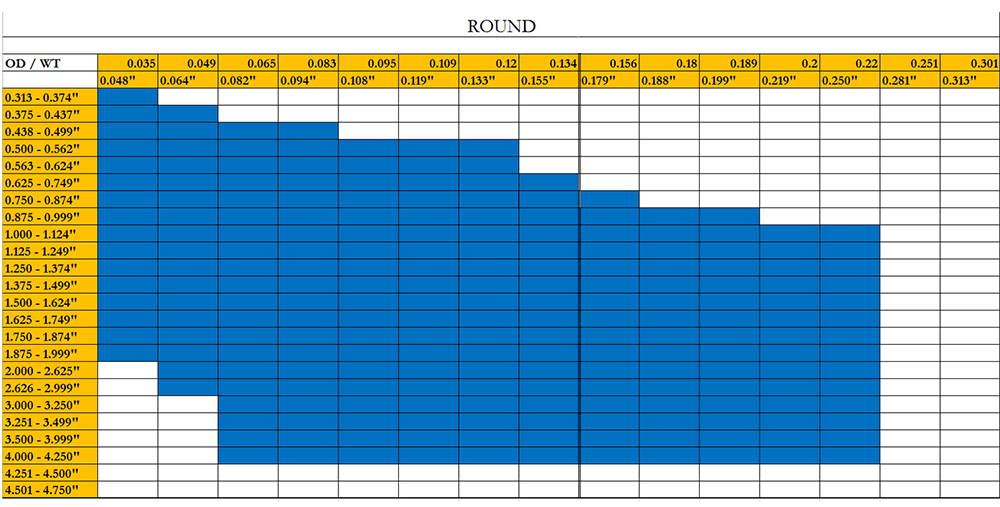

- .313”-4.25” outside diameter

- .035”-.25” wall thickness

- High precision

- Half standard commercial tolerances

- Superior strength

- Easy installation

- Controlled & uniform mechanical properties

- Smooth surface finish

- Uniform sectional thickness

Industrial Applications

General Engineering

- Bearings And Spindles, Trolley Handles,

- Hydraulic And Pneumatic Line, Electrical Conduit

- Oxygen Lancing Pipes, Cycle Pumps,

- Industrial Chain Roller, Gas Stove Lighters

- Electrostatic Precipitators

- Textile Frames And Bobbins

- Main Beam For Pedestal Fans

Automobiles

- Front Fork Top / Bottom

- Steering Column

- Two Wheeler Main Frame

- Bottom Chassis

- Fuel Tank Spacer

- Swing Arm

- Propeller Shaft

- Seat Frame

- Tie Rod

Technical Specifications

- ASTM A513 Type 5

- BS EN10305-2

- BS EN10305-3